Klebfix superglue

Cyanoacrylate structural adhesive, Klebfix

SUPGLU-SUPERFAST-20G

Register now and access more than 125,000 products

Clever special closure

- Precise dispensing

- The tips do not become clogged

Bonds in seconds

- Immediate further processing possible

- Fast repairs

- Simple designs without additional fastening materials possible

High level of resistance to ageing and climatic conditions

Solvent and silicone-free

NSF registered, class P1, reg. no. 151993

NSF-tested in accordance with NSF/ANSI 61 for use in service water and drinking water

- It is advisable to wear safety gloves and safety goggles.

- If surfaces are too dry or acidic, this will delay or prevent hardening, while higher levels of moisture and alkaline surfaces will have an accelerating effect.

- Due to the vapour pressure of the liquid adhesive, slow curing excess product around the adhesive area may result in a white deposit (blooming effect). These are adhesive vapours that are hardening. These can be removed with e.g. isopropanol or acetone. However, it is important to note that the surfaces of the parts to be cleaned are also resistant to these solvents. Blooming can be prevented/reduced by using the adhesive economically and ensuring sufficient air humidity and ventilation in the work area.

| Klebfix | Klebfix Plasto | Klebfix Flex | Klebfix 4-in-1 | Klebfix 4-in-1 Brush application | Klebfix GAN | Klebfix 2C | 089309 0893090 08930900 0893090030 | 0893091 | 0893092 | 0893423 | 0893094 | 0893403 08934031 | 0893093090 |

| Painted surfaces | Painted surfaces | – | – | – | – | ⚫ | ⚫ | ⚫ |

| Wood and wood materials | Wood (MDF, chipboard) | – | – | – | ⚫ | ⚫ | – | ⚫ |

| Laminated panels (Resopal, Ultrapas) | – | – | ⚫ | ⚫ | ⚫ | ⚫ | ⚫ | |

| Decorative panels | – | – | – | – | – | – | ⚫ | |

| Cork | ⚫ | ⚫ | ⚫ | ⚫ | ⚫ | ⚫ | – | |

| Stone and construction materials | Concrete | – | – | – | ⚫ | ⚫ | ⚫ | – |

| Bituminous surfaces | – | – | – | ⚫ | – | – | – | |

| Aerated concrete, gypsum, gypsum plasterboard | – | – | – | ⚫ | ⚫ | ⚫ | – | |

| Synthetic stone (Corian, Varicor) | ⚫ | – | ⚫ | – | – | – | ⚫ | |

| HPL | – | – | ⚫ | ⚫ | ⚫ | ⚫ | – | |

| Natural stone (marble, granite) | ⚫1 | – | ⚫ | – | – | ⚫ | ⚫ | |

| Stone | – | – | – | – | – | ⚫ | – | |

| Cemented fibreboards | – | – | – | ⚫ | ⚫ | ⚫ | – | |

| Other | Enamel | ⚫1 | – | ⚫ | – | – | – | – |

| Glass | ⚫ | – | ⚫ | ⚫ | ⚫ | ⚫ | ⚫ | |

| Fibre glass | – | – | – | ⚫ | ⚫ | – | ⚫ | |

| Mirror | ⚫1 | – | ⚫ | – | ⚫ | ⚫ | – | |

| Porcelain, ceramic, tiles | ⚫ | – | ⚫ | ⚫ | ⚫ | ⚫ | ⚫ | |

| Paper | – | – | ⚫ | ⚫ | ⚫ | ⚫ | ⚫ | |

| Cardboard | – | – | ⚫ | ⚫ | ⚫ | ⚫ | ⚫ | |

| Mesh | – | – | – | ⚫ | ⚫ | – | ⚫ | |

| Leather | – | – | – | ⚫ | ⚫ | – | – | |

| Metal | Aluminium | ⚫2 | – | ⚫2 | ⚫2 | ⚫2 | ⚫2 | ⚫ |

| Lead | – | – | ⚫ | ⚫ | ⚫ | ⚫ | – | |

| Stainless steel | – | – | ⚫ | ⚫ | ⚫ | ⚫ | ⚫ | |

| Copper | ⚫ | – | ⚫ | ⚫ | – | – | ⚫ | |

| Brass | – | – | ⚫ | ⚫ | – | – | ⚫ | |

| Steel/iron | ⚫ | – | ⚫ | ⚫ | ⚫ | – | ⚫ | |

| Zinc | – | – | ⚫ | ⚫ | ⚫ | ⚫ | ⚫ | |

| Plastics | ABS | – | ⚫ | – | ⚫ | ⚫ | ⚫ | ⚫ |

| GRP | ⚫ | ⚫1 | – | – | ⚫ | ⚫ | ⚫ | |

| EPDM | ⚫ | – | ⚫ | – | – | ⚫ | – | |

| Rubber | ⚫ | – | ⚫ | ⚫ | ⚫ | ⚫ | ⚫ | |

| Rigid foams | – | ⚫1 | ⚫1 | – | ⚫1 | ⚫1 | ⚫ | |

| Neoprene | – | – | ⚫ | – | – | – | ⚫ | |

| PE | – | ⚫1 | – | ⚫1 | ⚫1 | ⚫1 | ⚫1 | |

| PMMA | – | ⚫ | ⚫ | ⚫ | ⚫ | l | ⚫ | |

| Polyamide | – | – | – | – | – | – | ⚫ | |

| Polycarbonate = PC | ⚫ | – | ⚫ | ⚫ | ⚫ | ⚫ | ⚫ | |

| Polystyrene | – | ⚫1 | ⚫1 | ⚫ | ⚫ | ⚫ | ⚫ | |

| PP | – | ⚫1 | – | – | – | ⚫ | ⚫1 | |

| PTFE | – | ⚫1 | – | – | – | – | – | |

| PU | – | ⚫ | – | – | – | – | ⚫ | |

| PVC | – | ⚫ | ⚫ | ⚫ | ⚫ | ⚫ | ⚫ | |

| Silicone | – | – | ⚫1 | – | – | – | – | |

| Styrofoam | – | ⚫1 | ⚫1 | – | – | – | ⚫ | |

| 1. With primer 0893 091 5 2. With activator 0893 301 20 | ||||||||

NSF registered, class P1, reg. no. 151993

NSF-tested in accordance with NSF/ANSI 61 for use in service water and drinking water

The usage instructions are recommendations based on the tests we have conducted and on our experience; carry out your own tests before each application. Due to the large number of applications and storage and processing conditions, we do not assume any liability for a specific application result. Insofar as our free customer service provides technical information or acts as an advisory service, no responsibility is assumed by this service except where the advice or information given falls within the scope of our specified, contractually agreed service or the advisor was acting deliberately. We guarantee the consistent quality of our products. We reserve the right to make technical changes and further develop products. Please observe the technical data sheet!

Datasheets(X)

Superglue for bonding metal, plastic and rubber parts with and to each other.

The application surfaces must be clean, dry and free of grease. For pre-treatment, refer to the technical data sheet. Apply a thin, even layer of adhesive to just one of the surfaces to be adhered. Apply sufficient pressure to make the connection immediately, in order to ensure complete contact.

Chemical basis | Cyanoacrylate acidic ester |

Colour | Transparent |

Density | 1.06 g/cm³ |

Min./max. viscosity | 20-40 mPas |

Min. combined tension and shear resistance | 14 N/mm² |

Stretch capacity | 2 % |

Max. gluing gap size | 0.1 mm |

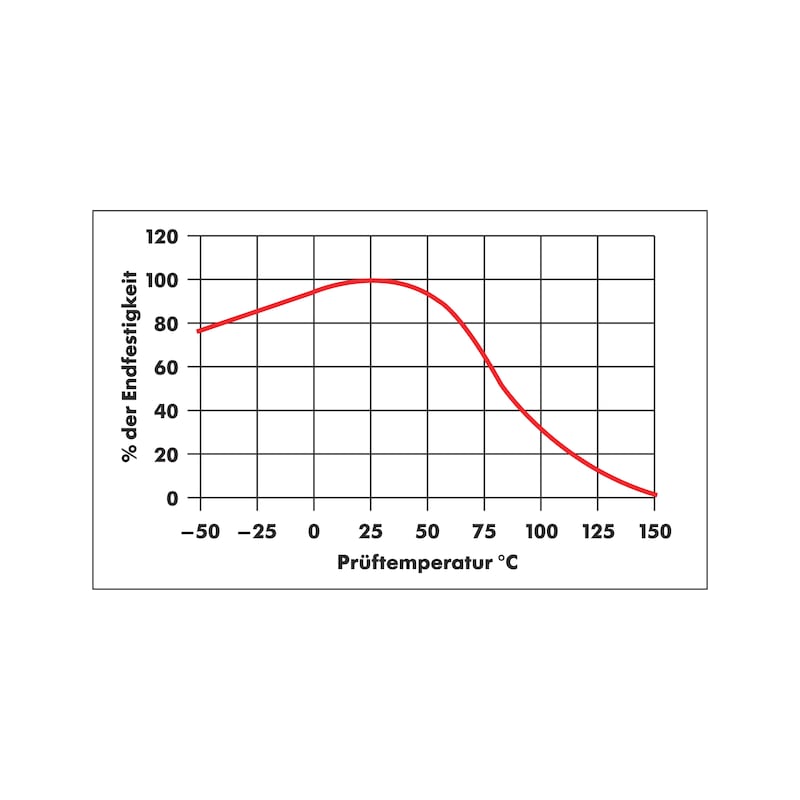

Min./max. temperature resistance | -30 to +80 °C |

Min./max. temperature conditions | -30 to 80 °C |

Min./max. processing temperature | 5 to 35 °C |

Silicone-free | Yes |

Solvent-free | Yes |

Shelf life from production/conditions | 15 Month / at room temperature |

Contents | 19 ml |

Weight of content | 20 g |

| Tensile shear strength values in compliance with DIN EN 1465 | |||

| 089309 + 0893090 | 08930900 | ||

| Material | Typical bonding times | Typical tensile lap-shear strength values (N/mm²) | Typical tensile lap-shear strength values (N/mm²) |

| Steel | 60−90 seconds | > 15 | > 15 |

| Aluminium | 60−90 seconds | > 14 | > 14 |

| PA | 20−30 seconds | 8–12 | 8-12 |

| PVC | 20−30 seconds | 10–20* | 10-20* |

| Polycarbonate | 10-15 seconds | 10–20* | 10-20* |

| POM | 30−40 seconds | – | - |

| EPDM | 5-9 seconds | > 10* | > 10* |

| Neoprene | 3−5 seconds | > 10* | > 10* |

| *Material breakage | |||

| Set to the touch after | 089309 + 0893090 | 08930900 |

| Aluminium / aluminium | ≥ 60 seconds | 40-90 seconds |

| SBR / SBR | ≥ 5 seconds | 3-10 seconds |

| Polycarbonate / polycarbonate | ≥ 10 seconds | 8-20 seconds |

| EPDM / EPDM | ≥ 7 seconds | ≤ 25 seconds |

| Curing speed is accelerated by using the activator | ||

Select RAL-colour code

!! NOTE: On-screen visualisation of the colour differs from real colour shade!!